“What’s the big difference?”

I have been asked the following question countless times throughout my career: “Why does my filter have a Beta Value associated with its efficiency, and why not just express that efficiency in terms of percent removal.” We all have a fundamental understanding of what “percent” means, and most of us can easily calculate percentage within a set of criteria. The real question is, does percent removal value accurately express the efficiency of a given filter within a system? To answer this, we must first understand how filter elements are rated, what that rating means, and how beta values relate to percent efficiency.

I have been asked the following question countless times throughout my career: “Why does my filter have a Beta Value associated with its efficiency, and why not just express that efficiency in terms of percent removal.” We all have a fundamental understanding of what “percent” means, and most of us can easily calculate percentage within a set of criteria. The real question is, does percent removal value accurately express the efficiency of a given filter within a system? To answer this, we must first understand how filter elements are rated, what that rating means, and how beta values relate to percent efficiency.

Suppose we want to understand how well our 10-micron filter element is performing in our process. We know it is 10-micron because that is what the part number says on the box. Furthermore, my trustworthy filter distributor assures me that this filter element has undergone stringent testing at the factory, and my element is “absolute rated”. However, what does that 10-micron rating mean, what is “absolute rated”, and what should I assume by that designation?

The truth is that there is no governing body that regulates industrial filter manufacturers on testing protocols and published efficiencies of filter medias. It is left up to the integrity of the given manufacturer to disclose how they arrived at a value, and the value is highly dependent on how the test is run. Therefore, it is not adequate to simply evaluate a filter element based on the part number on the box. Not all 10-micron elements are created equally, and “absolute rated” is a fairly meaningless statement without having a corresponding value (e.g. 99.0% and/or Beta 100). It is important to note that this value is a designation of the removal efficiency at a given particle size and larger (e.g., 10 micron). Therefore, a more adequate expression of the removal efficiency of a particular filter element should be expressed as follows:

99.0% efficient at removing particles 10 micron or larger

or

Beta10 = 100

This is a more accurate representation of how this filter element should perform in a process stream and gives a comparative value to other manufacturers (subject, of course, to their testing protocols as well). So, what do these two values tell us?

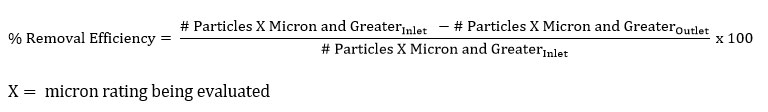

Percent Removal

Percent removal is calculated via the following formula:

Therefore, we can easily calculate our efficiency where we count 100,000 particles upstream and 1,000 particles downstream:

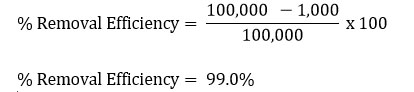

Beta Value

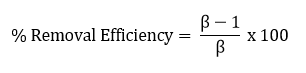

A Beta Value is simply a ratio of particles upstream and downstream:

It would appear that both values give us an accurate snapshot of the performance of our filter, and it would seem that there would be little difference in expressing the performance one way or the other. While this may be true, it can be demonstrated that expressing efficiency in a beta value is more precise in demonstrating filter performance. Consider the table below, which shows beta values and equivalent percent removal.

| Beta Ratio and Percent Removal Efficiency | |||

|---|---|---|---|

| Beta Value | % Removal Efficiency | # Particles Upstream | # Particles Downstream |

| 2 | 50.00% | 100,000 | 50000 |

| 4 | 75.00% | 100,000 | 25000 |

| 10 | 90.00% | 100,000 | 10000 |

| 20 | 95.00% | 100,000 | 5000 |

| 40 | 97.50% | 100,000 | 2500 |

| 75 | 98.67% | 100,000 | 1333 |

| 100 | 99.00% | 100,000 | 1000 |

| 200 | 99.50% | 100,000 | 500 |

| 500 | 99.80% | 100,000 | 200 |

| 1000 | 99.90% | 100,000 | 100 |

| 2000 | 99.95% | 100,000 | 50 |

| 5000 | 99.98% | 100,000 | 20 |

| 10000 | 99.99% | 100,000 | 10 |

One might assume that there is not a big difference between 99% and 99.9% removal efficiencies. I mean, it’s less than 1%, right? And, based on the chart above, if we have 100,000 particles coming into the filter there is only a difference of 900 particles between the two efficiencies (1000 vs. 100 particles counted downstream).

Keep in mind that this sample is only a snapshot in time and may only be a 100mL sample size. If we are evaluating a system of 100 gallons per minute, that is the equivalent of 378,541mL per minute. Considering that we have a difference of 900 particles between the two efficiencies and expanding our 100mL sample to the daily volumetric throughput the filter will handle, the performance difference between 99% and 99.9% efficiency is astounding. The 99% filter will allow 490,589,136,000 more particles to pass daily than the 99.9% efficient filter.

This value assumes consistent inlet quality and does not factor in changes in filter performance due to cake formation. However, it does demonstrate the significant difference in initial efficiencies between a filter rated at 99% and another filter rated at 99.9% that the rated value does not clearly imply. Now consider that a beta value gives us a more granular comparison between the two (Beta 100 vs. Beta 1000), and it implies the significant difference in performance that could otherwise be overlooked.

Remember this the next time you are evaluating your filter performance, or you are comparing two different filter manufacturers. If you have any questions or need help on your filter application, we at FTC would be happy to assist you with your needs, and we have a Distributor Partner in your area that would be happy to assist you as well.

John Worrell

Vice President of Sales

Filtration Technology Corporation